GAS BOOSTER PUMP

GAS BOOSTER PUMP

GAS BOOSTER PUMP SYSTEM

Air Driven Gas Boosters provide for pressures up to 80Mpa. Used for oil free compression not only of air,Oxygen or Nitrogen, but also flammable and risk gases like hydrogen, oxygenand natural gas. These boosters are ideal for increasing gas pressure, transferring high pressuregas,charging cylinders and scavenging.

Air driven boosters are an efficient alternative instead of electrically driven products andcan be used in explosion- proof areas.

As a result of the wide range of models it is possible to select the optimum booster for each application. Single stage, double acting or two stage boosters or a combination of these models can be used to achieve different operating pressures and flow capacities.

In order to select suitable booster pump or systems for you, kindly reply us the following questions:

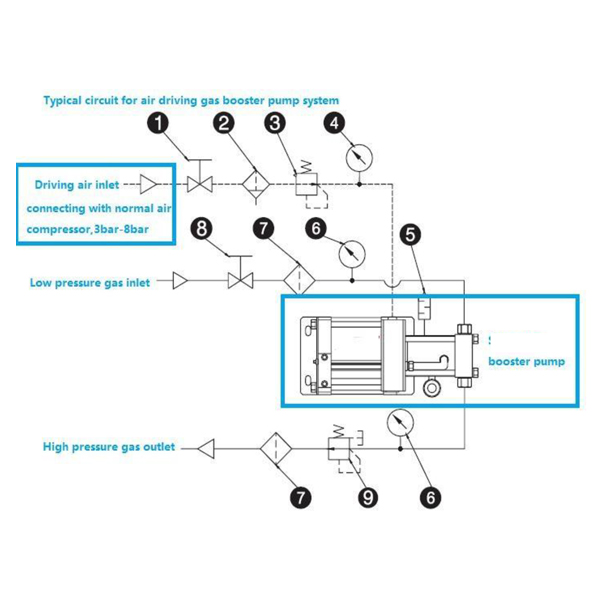

Number Explanation

1 drivinq air switch

2 air filter

3 air pressure adjusting valve

4 pressure gage

5 muffler

6 pressure gage

7 gas filter

8 needle valve

9 safetv relief valve

| Model | Pressure Boost Ratio | Min. gas Inlet Pressure PA (bar) | Max. gas Inlet Pressure PA (bar) | Max. gas outlet Pressure PB (bar) | Driven Air Pressure PL (bar) | Driven Air flow (CFM) | Connection (NPT thread) | Max. flow at driven air pressure of 6 bar | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Gas Inlet | Gas Outlet | (L/min) | Nm3/Hr | |||||||

| HB-02 | 2:1 | 1 | 16 | 16 | 2-8 | 30 | ½” | ½” | 960 (at PA of 6 bar) | 58 (at PA of 6 bar |

| HA-05 | 5:1 | 2 | 40 | 40 | 2-8 | 30 | ½” | ½” | 680 (at PA of 6 bar) | 40.8 (at PA of 6 bar) |

| HB-25 | 25:1 | 0.1 | 10 | 200 | 2-8 | 30 | 3/8” | ¼” | 156 (at PA of 8 bar) | 9.36 (at PA of 8 bar) |

| HB-30 | 30:1 | 3.4 | 10 | 249 | 2-8 | 30 | 3/8” | ¼” | 118 (at PA of 8 bar) | 7.08 (at PA of 8 bar) |

| 2HB7-25 | 25:1 | 5 | 56 | 200 | 2-8 | 50 | 3/8” | 3/8” | 300 (at PA of 8 bar) | 18 (at PA of 8 bar) |

| 2HB7-30 | 30:1 | 3.4 | 50 | 249 | 2-8 | 50 | 3/8” | 3/8” | 212 (at PA of 7 bar) | 12.72 (at PA of 7 bar) |

| HB-40 | 40:1 | 0.1 | 10 | 320 | 2-8 | 30 | 3/8” | ¼” | 124 (at PA of 8 bar) | 7.44 (at PA of 8 bar) |

| HD-60 | 60:1 | 25 | 480 | 480 | 2-8 | 30 | 3/8” | ¼” | 215 (at PA of 40 bar) | 12.9 (at PA of 40 bar) |

(Note: – PL: Driven air pressure, PA: Gas inlet pressure, PB: Gas outlet pressure)

• HB pumps are double acting, double stage with single air drive head pumps. They can provide for super high pressure with very low inlet pressure.

• High quality seals are used in pumps for providing better service life.

• SS parts are used in the pump for gas operations.