RECIPROCATING AIR COMPRESSOR

RECIPROCATING AIR COMPRESSOR

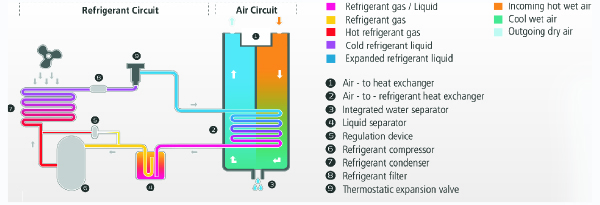

When atmospheric air cools down, as happens following a compressor compression process, water vapour precipitates as condensate. This is the form of water that is naturally present in the air we breathe. So, Compressed air contains oil, solid particles and water vapors. This untreated compressed air poses a substantial risk to your air system and end products. Its moisture content alone can cause corrosion in pipe work, premature failure of pneumatic equipment, product spoilage and more. An air dryer is therefore essential to protect your systems and processes

MARUTI PNEUMATICS’s refrigerant dryers provide the clean, dry air you need to expand the life of your equipment and ensure the quality of your products. Our dryers meet or exceed the international standards for compressed air purity and are tested according to ISO 7183:2007.

| REFRIGERATION COMPRESSOR | Low noise, Lasts longer thanks to limited vibrations, minimal moving parts and reduced risk of leakage. Industry recognized brand compressor with local support. |

|---|---|

| Digital display | Provides peace of mind through presize monitoring of pressure dew point |

| Hot Gas Bypass Valve | Ensures stable pressure dew point and prevents freezing at lower loads. |

| High Efficiency Heat Exchanger | Non corrosive heat exchanger, Design to have lower pressure drop & higher efficiency contains inbuilt moisture separator, Having dead zone to avoid carry over of condensate. |

| Integrated water separator | Low velocity with high separation efficiency even in low flow condition. |

| Condenser | High efficient copper tube & PUF insulated aluminum finned condenser |

| Fan Switch | Reduces energy consumption and optimizes the pressure dew point at very low temperature |

| Refrigerant Filter | Refrigerant filter insures the humidity that ensures the refrigerant system during refrigerant replacement does not clog the system |

| Zero Air Loss Condensate Drain (Optional) | The electric level control ensures proper draining of condensate and avoids unnecessary compressed air loss and ensure energy saving with noise free operation. Compressed air condenses moisture in dryers, after-coolers and air receivers. This condensate needs to be removed frequently. This process is done by the drain valves. In ordinary drains, there is always loss of compressed air. Most of the condensate drains have a 4 mm orifice. This 4 mm orifice bleeds about 34 cfm, which is the equivalent of 6.5 kw of power. This valve drains work on the principle of zero air loss and do not bleed your compressed air, consequently saving energy. |

Reference condition for Inlet flow capacity: Ambient temperature 25°C, Inlet compressed air temperature 35°C, Inlet Pressure – 7 barg All data mentioned above is for Air cooled versions according to ISO 7183, with standard voltage, at 3-5’C pressure dew point. Water cooled versions, high pressure dryers and high ambient temperature dryers are available on request.

| Inlet Air Pressure | Barg | 4 | 5 | 6 | 7 | 8 | 10 | 12 | 14 |

|---|---|---|---|---|---|---|---|---|---|

| Factor F1 | 0.77 | 0.86 | 0.93 | 1.00 | 1.05 | 1.14 | 1.21 | 1.27 |

| Ambient Temperature | ‘C | <=25 | 30 | 35 | 40 | 45 |

|---|---|---|---|---|---|---|

| Factor F2 | 1.25 | 1.10 | 1 | 0.95 | 0.86 |

| Inlet Air Temperature | ‘C | <=30 | 35 | 40 | 45 | 50 | 55 | 60 |

|---|---|---|---|---|---|---|---|---|

| Factor F3 | 1.15 | 1.00 | 0.95 | 0.90 | 0.65 | 0.59 | 0.53 |

How to calculate dryer minimum nominal Actual rated capacity

capacity to meet rated condition F1 x F2 xF3

|

Model |

Inlet Flow Capacity |

Max. working Pressure |

Power Supply

|

Nominal Power Consumption |

Air Connection Size (In/Out) |

Cooling Media |

|

|

Scfm |

Bar |

V / Ph / Hz |

KW |

|

Air |

|

RP 02 |

20 |

16 |

230/1/50 |

0.15 |

½” BSP-F |

Air |

|

RP 04 |

40 |

16 |

230/1/50 |

0.20 |

½” BSP-F |

Air |

|

RP 06 |

60 |

16 |

230/1/50 |

0.39 |

¾” BSP-F |

Air |

|

RP 08 |

80 |

16 |

230/1/50 |

0.40 |

1” BSP-F |

Air |

|

RP 10 |

100 |

16 |

230/1/50 |

0.50 |

1” BSP-F |

Air |

|

RP 12 |

125 |

16 |

230/1/50 |

0.65 |

1” BSP-F |

Air |

|

RP 15 |

150 |

16 |

230/1/50 |

0.70 |

1” BSP-F |

Air |

|

RP 20 |

200 |

16 |

230/1/50 |

0.80 |

1 ½” BSP-F |

Air |

|

RP 25 |

250 |

16 |

230/1/50 |

0.90 |

1 ½” BSP-F |

Air |

|

RP 30 |

300 |

16 |

450/3/50 |

1.00 |

1 ½” BSP-F |

Air |

|

RP 40 |

400 |

16 |

450/3/50 |

1.40 |

2” BSP-F |

Air |

|

RP 50 |

500 |

16 |

450/3/50 |

1.50 |

2” BSP-F |

Air |

|

RP 60 |

600 |

14 |

450/3/50 |

2.05 |

DN80-PN16 |

Air |

|

RP 70 |

700 |

14 |

450/3/50 |

2.20 |

DN80-PN16 |

Air |

|

RP 80 |

800 |

14 |

450/3/50 |

2.80 |

DN80-PN16 |

Air |

|

RP 100 |

1000 |

14 |

450/3/50 |

3.00 |

DN80-PN16 |

Air |

|

RP 125 |

1250 |

14 |

450/3/50 |

4.20 |

DN80-PN16 |

Air |

|

RP 150 |

1500 |

14 |

450/3/50 |

4.50 |

DN100-PN16 |

Air |

|

RP 175 |

1750 |

14 |

450/3/50 |

5.20 |

DN100-PN16 |

Air |

|

RP 200 |

2000 |

14 |

450/3/50 |

5.70 |

DN100-PN16 |

Air |

|

RP 300 |

3000 |

14 |

450/3/50 |

6.60 |

DN100-PN16 |

Air |

*The company on product improvement and right of design improvement, parameters are subjected to change without prior notice

*Above model available with optional zero air loss drain valve